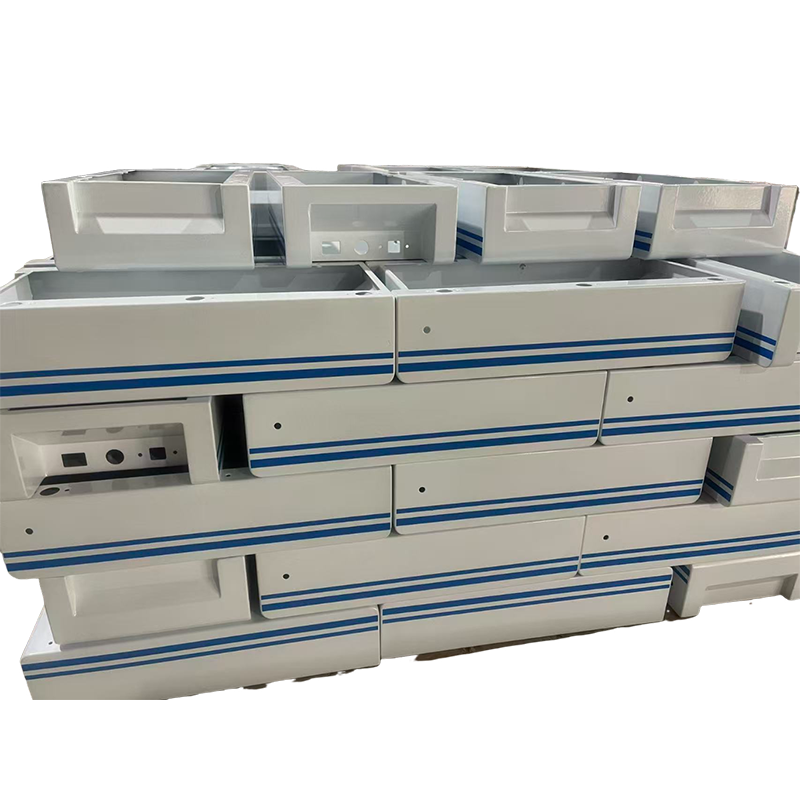

CNC machining is not a singular process but a comprehensive category that includes various sub-processes tailored to different manufacturing needs. Below are the most common types of CNC machining:

1. CNC Milling

One of the most widely used processes, CNC milling involves a rotating cutting tool that removes material from a stationary workpiece. It is ideal for creating flat surfaces, pockets, slots, and complex 3D shapes.

2. CNC Turning

Primarily used for cylindrical components, CNC turning spins the workpiece while a single-point cutting tool shapes the material. It is efficient for producing shafts, bushings, and threaded parts.

3. CNC Drilling

Used to create precise holes in a variety of materials. CNC drilling machines often integrate functions like countersinking, tapping, and reaming to achieve finished hole profiles.

4. CNC EDM (Electrical Discharge Machining)

Utilized for extremely hard materials or intricate cavities that are difficult to machine using traditional methods. EDM processes include wire EDM and sinker EDM.

5. Multi-Axis CNC Machining

Advanced CNC machines (3-axis, 4-axis, 5-axis, and even 6-axis) allow simultaneous movement in multiple directions, enabling high-precision manufacturing of complex geometries in a single setup.

Each process can be used independently or in combination to meet specific engineering and design requirements.