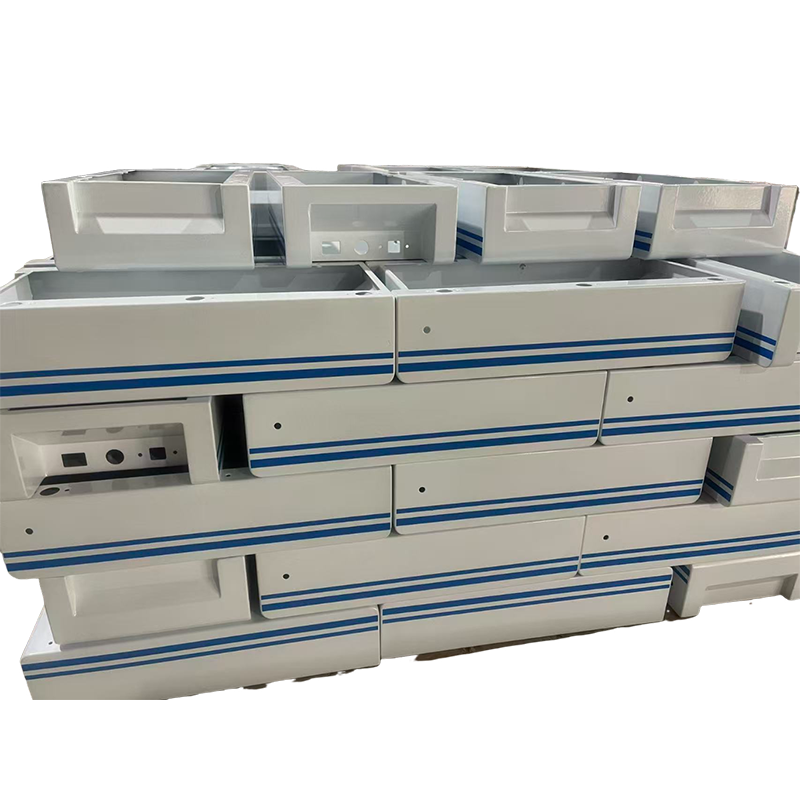

CNC machining is incredibly versatile and can handle a wide range of metals and plastics.

Common Metals:

-

Aluminum Alloys (e.g., 6061, 7075) – Lightweight, corrosion-resistant, excellent for aerospace and electronics.

-

Stainless Steel (e.g., 304, 316) – Strong, corrosion-resistant, ideal for medical and food-grade applications.

-

Titanium Alloys – High strength-to-weight ratio, commonly used in aerospace and implants.

-

Copper & Brass – Excellent conductivity and machinability, used for electrical and decorative parts.

-

Carbon Steel – Strong and cost-effective, widely used for structural and mechanical components.

Engineering Plastics:

POM (Delrin), PEEK, Nylon, Acrylic, Polycarbonate (PC), PTFE (Teflon), ABS, and more.

Note: Different materials require different machining approaches. For example, titanium requires slower speeds and advanced cooling due to poor heat dissipation, while plastics need careful control of feed rate and temperature to prevent deformation.