Engineers often face a difficult challenge in electrical design. You must balance high conductivity with mechanical strength today. Many materials fail to meet both requirements effectively now. Aluminum often lacks the necessary durability for connectors. Copper is highly conductive but very difficult to machine. This struggle leads to higher costs and slower production. However, brass CNC turning mechanical parts offer a perfect middle ground. This material provides excellent electrical properties and easy machinability. You can achieve complex shapes without sacrificing performance at all. Discover how the right parts improve your power systems. Your journey to superior electrical engineering starts right here. Let us explore the benefits of brass CNC turning now.

The Scientific Edge of Brass in Electronics

Brass CNC turning mechanical parts dominate the electronics market today. Specifically, brass alloys contain high levels of copper and zinc. This combination ensures a very low electrical resistance. Consequently, current flows smoothly through these precision-machined components. Furthermore, brass offers a natural resistance to environmental corrosion. This is vital for parts used in outdoor power grids. Most high precision brass turned components maintain their integrity for years. Reliability defines the success of modern telecommunication systems. You need parts that stay conductive under heavy stress. Brass meets these demands with absolute technical consistency. Every turned part contributes to a more stable power network.

Machinability Meets High-Performance Engineering

Why do manufacturers prefer brass for complex electrical connectors? Specifically, C36000 brass CNC machining services provide incredible speed. This alloy is also known as “Free-cutting brass” today. It allows machines to run at very high speeds. Therefore, you reduce the production time for every single part. Furthermore, high-speed turning creates a superior surface finish. A smooth surface ensures better contact in electrical junctions. Consequently, you minimize heat buildup during high-voltage operations. This efficiency protects the entire system from potential failure.

The Role of Zinc in Mechanical Stability

Pure copper is often too soft for threaded components. Specifically, the zinc in brass adds necessary physical hardness. This allows for the creation of custom CNC brass parts for electronics. You can cut deep, precise threads that never strip. Furthermore, these parts withstand high torque during assembly processes. This mechanical strength is essential for heavy-duty battery terminals. Moreover, brass remains stable across wide temperature ranges. Therefore, your electrical connections stay secure in extreme heat. Stability and conductivity go hand in hand with brass.

Achieve Peak Performance with Precision Brass

Imagine a system with zero power loss at the joints. You want connectors that never corrode or fail. Using brass CNC turning mechanical parts makes this possible. You no longer worry about expensive maintenance or downtime. Instead, you focus on delivering high-quality power solutions. Experience the professional pride of a perfectly engineered system. Your clients will trust your hardware for its reliability. Better components lead to a much stronger market reputation. Premium brass parts turn a standard device into a leader. You deserve a material that works as hard as you. Reach new heights of efficiency with CNC turned brass.

Why Global Tech Brands Choose CNC Turned Brass?

Modern manufacturing requires speed without any loss in quality. See why low lead brass mechanical parts for connectors are vital:

-

Fast Heat Dissipation: Brass prevents overheating in high-current boards.

-

Non-Magnetic Properties: Ideal for sensitive medical and imaging equipment.

-

Antibacterial Surfaces: Naturally kills bacteria in touch-sensitive devices.

-

High Recyclability: Lowers the environmental footprint of your factory.

-

Cost Efficiency: Cheaper than silver or gold plating for conductivity.

Material Performance Comparison for Turning

| Material Property | Pure Copper | C36000 Brass | 6061 Aluminum |

| Electrical Conductivity | Highest (100% IACS) | High (26-28% IACS) | Medium (43% IACS) |

| Machinability Rating | Poor (20%) | Excellent (100%) | Good (50%) |

| Corrosion Resistance | Moderate | High | High |

| Thread Strength | Low | High | Medium |

| Material Cost | High | Moderate | Low |

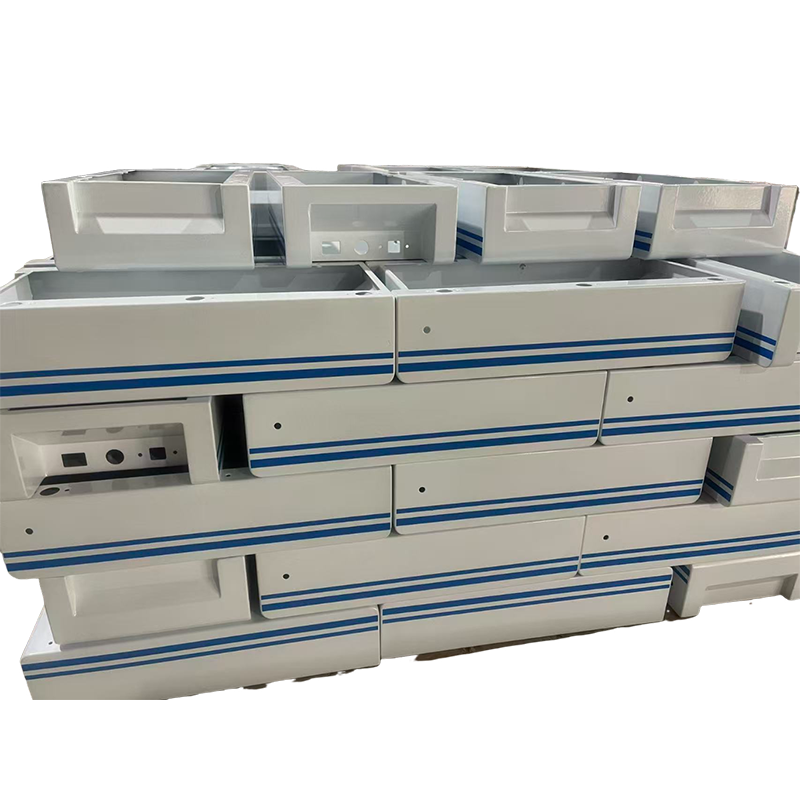

Optimize Your Electrical Supply Chain Today

The 2026 industrial market demands more efficient power systems. Do not let inferior materials slow down your innovation. Explore our latest brass CNC turning mechanical parts today. We offer custom solutions for every complex electrical need. Our team provides fast prototyping and high-volume production now. Furthermore, we ensure all parts meet strict international standards. Improve your conductivity and slash your maintenance costs today. Take the first step toward a more reliable product. Contact us for a technical consultation on your next project.

Ready to Enhance Your Component Quality?

-

Evaluate your current electrical loss at connection points.

-

Check out our high precision brass turned components gallery.

-

Inquire about custom CNC brass parts for electronics pricing.

-

Select C36000 brass CNC machining services for fast delivery.

-

Start your journey to better conductivity with us tonight.

Visit our official site to browse our brass turning gallery. Read case studies from engineers who improved their designs. Find the perfect balance between high performance and cost. The future of your hardware depends on your material choice. Contact us today to secure your ultimate brass parts!

Precision Brass is the Future of Power

In 2026, every milliwatt of power efficiency matters. High-quality brass CNC turning mechanical parts are essential tools. They protect your circuits and ensure lasting conductivity. Make your engineering as reliable as your own vision. Your best electrical results begin with CNC turned brass.

FAQ

1. Why is C36000 brass the standard for CNC turning?

C36000 is the best alloy for high-speed machining. Specifically, it allows for extremely tight tolerances and smooth finishes. It is the core of brass CNC turning mechanical parts production. Consequently, you get cheaper parts with much higher precision.

2. Can brass parts be used in high-voltage environments?

Yes, brass is excellent for high-voltage connectors and terminals. Specifically, it handles heat much better than aluminum or plastic. Furthermore, its mechanical strength ensures the connection stays tight. This prevents dangerous electrical arcing in your heavy equipment.

3. Is brass better for conductivity than stainless steel?

Yes, brass is much more conductive than stainless steel. Specifically, brass has an IACS rating of around 28%. Stainless steel usually stays below 5% for most common grades. Therefore, brass is the superior choice for any electrical application.