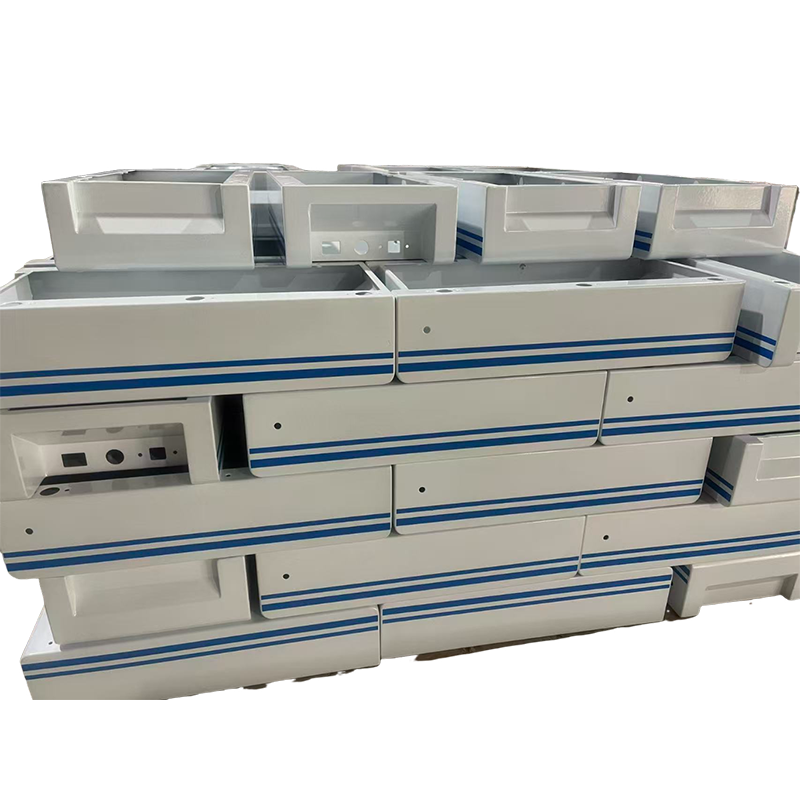

Design engineers often focus solely on part geometry today. You spend weeks perfecting every single dimension now. However, raw metal often looks dull and unfinished. Raw custom machined aluminum parts also oxidize very quickly. This lead to corrosion and poor mechanical performance. 🛑 Your high-end product deserves a much better look. A great finish adds both beauty and durability. It also protects your investment from harsh environments. Discover how the right surface treatment changes everything. Your journey to a premium product starts right here. Let us explore the best aluminum finishes now.

Why Surface Treatment Matters for Aluminum

Aluminum is a versatile and very popular material. Specifically, it offers a great strength-to-weight ratio. However, its surface is naturally quite soft. Therefore, custom machined aluminum parts need extra protection. Surface finishes improve wear resistance and electrical insulation. Furthermore, they can change the color and texture. 💡 This flexibility is vital for modern consumer electronics. Professional precision CNC aluminum finishing services offer many options. Every choice affects the final feel of your part. Most engineers want a balance of cost and quality. Consequently, choosing the right method requires deep technical knowledge. Reliability starts with the outer layer of your component.

The Science of Anodizing for Durability

Why is anodizing the most popular choice for aluminum? Specifically, it creates a hard protective oxide layer. Anodized aluminum CNC components resist scratches and corrosion. This process also allows for vibrant color dyes. Therefore, you can match your part to your brand. Furthermore, anodized layers do not peel or flake. Consequently, your product stays looking new for years. This is essential for medical and aerospace applications.

Achieving Aesthetic Perfection with Bead Blasting

Do you want a smooth and matte appearance? Specifically, a bead blasted aluminum surface texture is ideal. High-pressure air fires tiny glass beads at the metal. This removes tool marks from the CNC process. Furthermore, it creates a very uniform and satin finish. Therefore, it feels premium and professional in the hand. Many tech companies use this for laptop housings. Consequently, it hides fingerprints and minor surface scratches. It is the perfect blend of style and function.

Achieve Peak Performance and Visual Appeal

Imagine your components looking like a work of art. 🌟 You want a finish that stays perfect forever. Using the right treatment for custom machined aluminum parts makes this real. You no longer worry about rust or wear. ✨ Instead, you focus on winning more market share. Experience the professional pride of a high-quality finish. 🌟 Your clients will notice the superior craft and detail. Better finishes lead to much higher product value. Premium coatings turn a basic part into a leader. You deserve a finish that matches your 2026 vision. Reach new levels of excellence with expert finishing.

Comparing Popular Aluminum Finishing Options

| Finish Type | Durability | Aesthetic Appeal | Main Benefit |

| As-Machined | Low | Industrial | Low cost and fast |

| Anodizing | Very High | Excellent | Corrosion resistance |

| Bead Blasting | Medium | High | Hides tool marks |

| Powder Coating | High | Versatile | Many color options |

| Electroless Nickel | Highest | Functional | Extreme wear protection |

The Functional Edge of Chemical Film Coating

Sometimes you need conductivity and protection together. Specifically, “Chem Film” or Alodine is the solution. It provides a clear coat for machined aluminum look. However, it still allows electricity to pass through. Furthermore, it serves as a great base for paint. Therefore, it is very popular in the military sector. Consequently, your parts stay protected without losing functionality. It is a cost-effective way to prevent early oxidation.

Elevate Your Machined Parts Today

The 2026 manufacturing season demands the highest standards. Do not settle for raw and unprotected metal parts. Explore our latest finishing options for custom machined aluminum parts now. We offer everything from Type III Hardcoat to polishing. 📦 Our team provides full technical support for your project. Furthermore, we ensure every part passes strict QC checks. Improve your product life and aesthetic appeal right now. 🛒 Take the first step toward a superior build. Contact our finishing experts for a free consultation today.

Ready to Optimize Your Aluminum Components?

-

Check out our precision CNC aluminum finishing services.

-

Research the benefits of anodized aluminum CNC components.

-

Request a sample of bead blasted aluminum surface texture.

Visit our official site to browse our finish gallery. Find the perfect balance between protection and visual style. The future of your product depends on the finish. Contact us today to secure your ultimate aluminum solution! 🖱️

The Finish is the Final Signature

In 2026, details determine the success of your brand. High-quality custom machined aluminum parts require a great finish. It protects your work and impresses your customers. Make your product as durable as your own vision. Your best results begin with the perfect surface. 🥂

FAQ

1. Can anodizing change the dimensions of my parts?

Yes, anodizing adds a very thin layer of oxide. Specifically, Type II adds about 5 to 25 microns. Therefore, you must account for this during the design. Consequently, your tight tolerances will remain perfect after treatment. ✅

2. Which finish is best for outdoor use?

Hardcoat Anodizing or Powder Coating are the best choices. Specifically, they offer the highest resistance to UV and rain. Furthermore, they protect the metal from salt and chemicals. Therefore, your outdoor equipment will last for many decades. ☀️

3. Does bead blasting remove deep CNC tool marks?

It hides light marks but cannot fix deep gouges. Specifically, it creates a uniform texture across the surface. However, you should request a fine finish before blasting. Consequently, you will achieve the smootest matte look possible. 🛠️