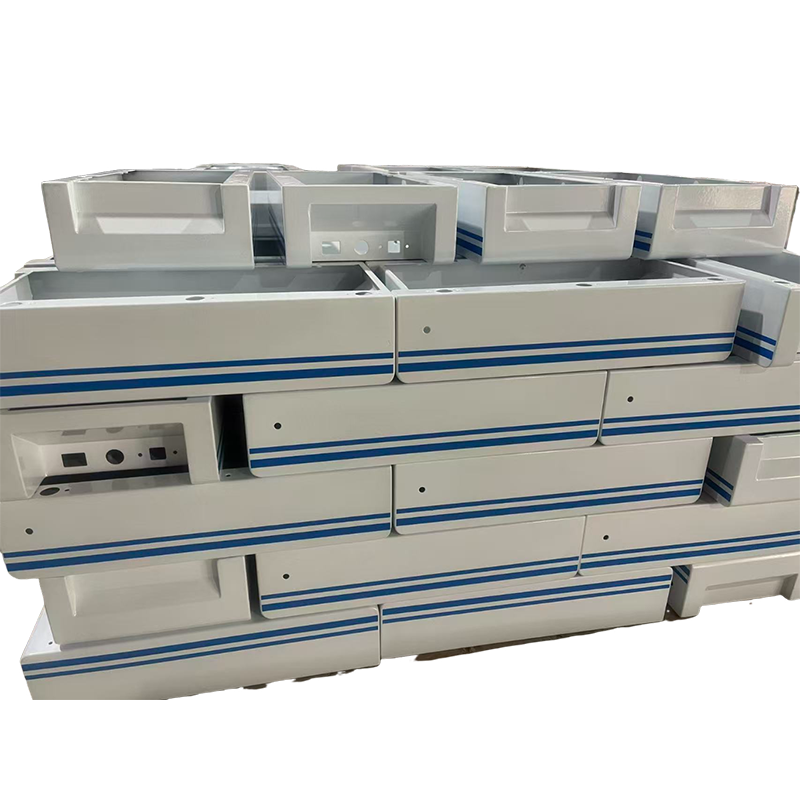

Aluminum remains a top choice for modern engineering. However, the raw finish rarely meets high industry standards. Today, manufacturers demand more from their aluminum CNC machining parts. They want better durability, striking aesthetics, and eco-friendly processes.

The world of surface finishing is changing fast in 2026. New technologies allow for thinner yet stronger coatings. Consequently, engineers can now achieve incredible precision and protection. This article explores the hottest trends in aluminum finishing today. We will help you choose the best path for your project.

The Shift Toward Sustainable Finishing Processes

Sustainability is no longer just a buzzword. Indeed, it is now a strict regulatory requirement. Many traditional finishing methods used harsh, toxic chemicals. But modern trends favor greener, safer alternatives for the planet.

Chrome-Free Conversion Coatings

In the past, many shops used hexavalent chromium. This chemical provides great protection but harms the environment. Today, most experts move toward trivalent or chrome-free coatings. These options offer excellent corrosion resistance without the toxic waste. Therefore, they are the new gold standard for high-performance parts.

Water-Based Anodizing Systems

Anodizing is the most popular treatment for aluminum. New water-recycled systems now reduce total water waste. These closed-loop systems filter and reuse chemical baths. As a result, factories lower their environmental footprint significantly. This trend appeals greatly to eco-conscious global brands.

Advanced Anodizing: Beyond Basic Colors

Anodizing has evolved far beyond simple black or silver. Engineers now use it to enhance the physical properties of aluminum CNC machining parts.

Hard Coat Anodizing (Type III)

Standard anodizing provides a thin protective layer. However, Type III anodizing creates a very thick, ceramic-like surface. It offers extreme wear resistance for aerospace components. This trend is growing in the robotics and automotive sectors. It allows aluminum to replace much heavier steel components.

Micro-Arc Oxidation (MAO)

MAO is a cutting-edge plasma-based electrolytic process. It creates an incredibly hard, crystalline oxide coating. This finish handles high temperatures and intense friction easily. Many medical device manufacturers now prefer MAO for its biocompatibility. It is a premium choice for high-end industrial applications.

High-Precision Aesthetic Finishes for Electronics

Consumer electronics require a perfect tactile feel. Because of this, “bead blasting” has seen a major upgrade. Designers now demand specific “RA” values for surface roughness.

-

Micro-Bead Blasting: This creates a soft, satin-like matte finish.

-

Bright Dipping: This chemical process creates a mirror-like shine.

-

Chemical Polishing: It removes microscopic burrs for a smooth touch.

-

Laser Texturing: Lasers create intricate patterns or logos directly on metal.

These methods ensure your aluminum CNC machining parts look premium. They also hide fingerprints and resist minor scratches during daily use.

The Rise of Functional PVD Coatings

Physical Vapor Deposition (PVD) was once reserved for watches. Now, it is common for industrial aluminum parts. PVD applies a thin film of metal or ceramic.

This coating is much thinner than traditional paint or powder. Therefore, it does not change the part’s final dimensions. It provides a unique metallic color that will never fade. PVD also adds significant surface hardness to the aluminum substrate. Consequently, it is ideal for parts with very tight tolerances.

Integrated Digital Color Matching Trends

Consistency is vital for large-scale production runs. In 2026, digital color matching has become the industry norm. Manufacturers use AI-powered spectrophotometers to verify every batch.

This ensures that parts from different lots match perfectly. This technology eliminates human error in the dying process. It is especially important for brands with specific corporate colors. If your color is off, your brand image suffers. Digital tools provide the precision that modern markets demand.

Why Surface Treatment Matters for Aluminum CNC Machining Parts

Choosing a finish is not just about looks. It is a critical engineering decision. The right treatment prevents oxidation in harsh environments. It also provides electrical insulation or improves conductivity.

-

Corrosion Protection: Essential for marine or outdoor applications.

-

Wear Resistance: Necessary for moving parts or gears.

-

Heat Dissipation: Vital for high-performance heat sinks.

-

Adhesion Improvement: Prepares the surface for secondary painting.

Without proper treatment, aluminum can degrade or seize over time. Thus, finishing is the final step in quality assurance.

Selecting Your Best Finish

Surface treatment trends are moving toward precision and sustainability. You must balance cost, durability, and aesthetics for success. Whether you choose PVD or MAO, quality is the key.

Always consult with your machinist early in the design phase. They can help you optimize your CNC machining parts. Proper finishing ensures your project stands the test of time. Stay ahead of these trends to remain competitive in 2026.