Manufacturing success depends on extreme precision today. One tiny error can ruin a whole project now. You likely face pressure to find reliable parts fast. However, many suppliers fail to meet tight tolerances consistently. Poor quality control leads to expensive product recalls. It also damages your brand’s reputation in the market. You need a cnc machine parts manufacturer you can trust. High-quality parts require more than just advanced machines. They require a rigorous and scientific inspection process. Discover how global leaders maintain 100% accuracy every day. Your journey to manufacturing excellence starts right here. Let us explore the world of elite quality control.

The Science of Precision CNC Machining Quality Control

Professional CNC machine tool parts manufacturers will never let quality issues become a problem. Specifically, they implement precise CNC machining quality control at every stage. This process begins even before the machines are started. Engineers first review the product design and assess its manufacturing feasibility. They identify potential risks in terms of geometry or materials. Furthermore, they calibrate all measuring tools according to international standards. This foundation ensures the accuracy of every data point. A digital tracking system monitors the production floor in real time. Therefore, operators can detect and correct deviations before they develop into defects. Reliability is at the heart of success in modern industry today. Every step must serve the goal of achieving perfect precision.

Material Verification and Raw Supply Audit

Why does quality start with the raw material? Specifically, the wrong alloy can cause catastrophic part failure. An iso certified cnc machine shop always verifies material certificates. They use Spectrometers to check the chemical composition now. This ensures the metal meets your exact strength requirements. Furthermore, they inspect the material for internal stress or cracks. Therefore, your parts remain stable during the machining process. High-quality input leads to high-quality output every time.

In-Process Inspection and Real-Time Monitoring

Modern factories do not wait until the end to check. Specifically, they perform “First Article Inspection” for every new batch. Operators check the first part against the CAD model. If it passes, the full production run begins immediately. Furthermore, robots often perform mid-run checks using laser sensors. This allows for instant adjustments to the cutting tools. Consequently, tool wear never affects the final dimensions. Consistency is the hallmark of an elite manufacturer today.

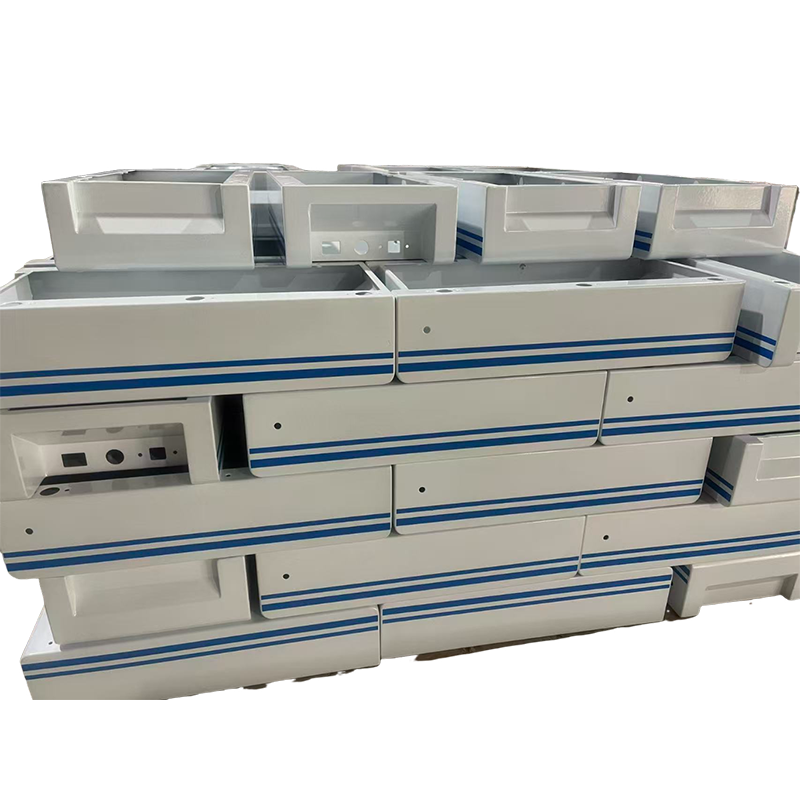

Achieve Perfection with High Tolerance CNC Components

Imagine receiving a shipment where every part is perfect. You want components that fit your assembly flawlessly. Partnering with a top cnc machine parts manufacturer makes this real. You no longer worry about expensive rework or delays. Instead, you focus on scaling your business globally. Experience the professional pride of using elite-level hardware. Your clients will notice the difference in your products. Better parts lead to a much stronger market position. When you choose Chongxi, you secure your engineering future. We turn complex designs into high-precision reality every day. Reach new heights of success with our advanced QC.

The Importance of Final Inspection and Metrology

Final checks are the last line of defense. See why high tolerance cnc components inspection is so vital:

-

CMM Testing: Measures complex 3D shapes with micron precision.

-

Surface Roughness: Ensures the finish meets your specific friction needs.

-

Thread Gauging: Verifies that every screw fits perfectly every time.

-

Hardness Testing: Confirms the heat treatment achieved the correct strength.

-

Visual Audit: Checks for cosmetic defects or tiny burrs.

CNC Quality Control Process Comparison

| QC Stage | Traditional Workshop | Global Manufacturer (Chongxi) |

| Material Check | Visual Only | Spectrometer Analysis |

| Tool Calibration | Occasional | Daily Digital Sync |

| Inspection Data | Paper Logs | Cloud-Based Real-Time Data |

| Tolerances | +/- 0.1 mm | Up to +/- 0.005 mm |

| Reporting | Basic Receipt | Full Dimensional QC Report |

Secure Your Precision Supply Chain Today

The 2026 industrial market demands speed and total accuracy. Do not settle for “good enough” in your production. Partner with an expert cnc machine parts manufacturer right now. We offer custom 5 axis cnc parts manufacturing for all industries. Our team provides full QC documentation for every order. Furthermore, we offer DFM feedback to lower your costs. Improve your product performance and lower your risks today. Choose Chongxi for your next high-precision project. Take the first step toward a more reliable partnership. Contact our engineers for a technical quote today.

Ready to Elevate Your Part Quality?

-

Inquire about our precision cnc machining quality control.

-

Verify our iso certified cnc machine shop credentials.

-

Start your journey to zero-defect manufacturing tonight.

Visit our official site to browse our equipment gallery. Read case studies from leaders who trust our precision. Find the perfect balance between high speed and cost. The future of your brand depends on your parts. Contact us today to secure your ultimate CNC solution!

Quality is the Only Path to Growth

In 2026, precision is the language of global business. A world-class cnc machine parts manufacturer is your best ally. They protect your designs and ensure your project’s success. Make your supply chain as accurate as your vision. Your best industrial results begin with rigorous quality control.

FAQ

1. What is a CMM and why is it important?

A CMM is a Coordinate Measuring Machine for 3D. Specifically, it measures the physical geometry of a part. It ensures that complex parts meet the CAD design. Consequently, you get 100% accuracy for every single dimension.

2. How do you ensure material honesty in CNC?

We use Spectrometers to verify the raw metal alloy. Specifically, we match the chemical signature to the certificate. This prevents the use of cheap or weak materials. Therefore, your parts always meet the required tensile strength.

3. Can you provide a full QC report with my order?

Yes, we provide detailed dimensional reports for every batch. Specifically, we list every critical measurement and its tolerance. This transparency builds trust and ensures assembly line success. Most global clients require this level of detail today.