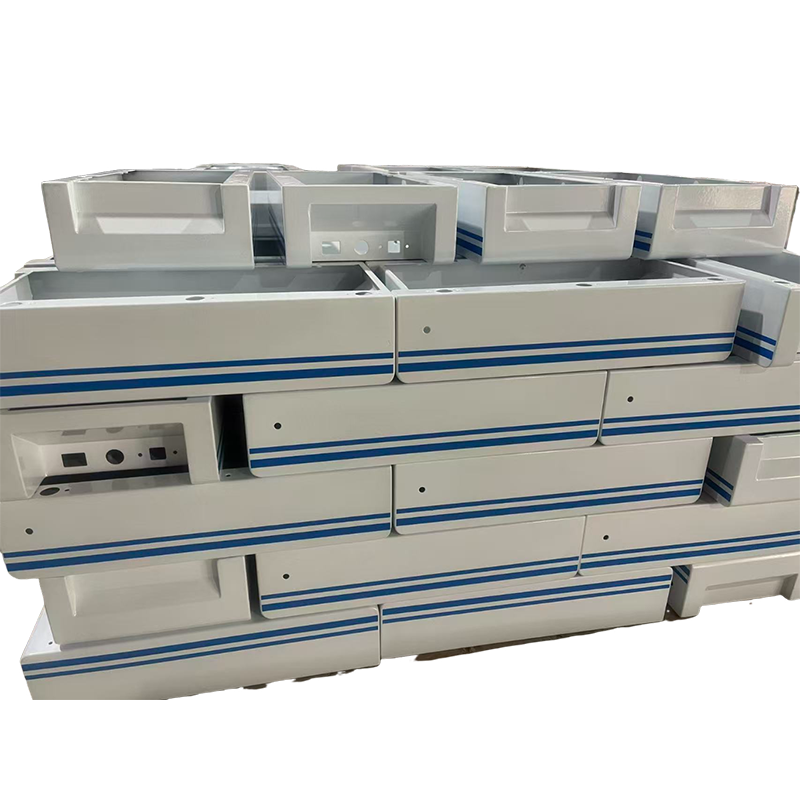

In 2026, the demand for extreme accuracy is skyrocketing. Industries like aerospace and medical tech require incredible precision. Specifically, hitting a tolerance of +/- 0.001 mm is a massive challenge. This level of detail represents the pinnacle of modern manufacturing.

However, achieving this consistency requires more than just good machines. You need a perfect blend of technology and environment. High-quality cnc precision machining parts depend on every tiny detail. This guide explains the secrets to mastering ultra-fine tolerances. We will help you transform your production quality today.

The Role of High-End Machine Tool Selection

You cannot achieve micron-level accuracy with basic equipment. Therefore, you must invest in high-precision CNC centers. These machines must have exceptional structural rigidity.

Why Thermal Stability Matters

Metal expands and contracts with even slight temperature changes. Consequently, machines must feature advanced thermal compensation systems. These systems use sensors to track heat in real-time. Then, the software adjusts the tool path automatically. This ensures your cnc precision machining parts stay accurate all day.

High-Resolution Encoders

Precision depends on how well the machine knows its position. Use linear scales with sub-micron resolution for better feedback. These encoders prevent errors caused by lead screw backlash. This level of control is vital for complex geometries.

Controlling the Production Environment

The environment is the silent enemy of precision. If the room temperature fluctuates, your tolerances will fail.

-

Climate Control: Keep the workshop at a constant 20°.

-

Vibration Isolation: Install machines on specialized heavy-duty foundations.

-

Humidity Management: Prevent oxidation or material changes with dry air.

-

Cleanliness: Dust particles can ruin a +/- 0.001 mm measurement.

Professional shops treat their floor like a laboratory. This control allows for repeatable CNC precision machining parts. Without a stable environment, micron-level work is simply impossible.

Cutting Tool Selection and Management

Your cutting tools must be as precise as the machine. Even slight wear can push parts out of spec.

Material-Specific Tooling

Use diamond-coated or cubic boron nitride (CBN) tools for hardness. These materials maintain their sharp edge much longer. Sharp tools reduce cutting forces and minimize part deflection. This is critical when working with thin-walled components.

Tool Holder Balance

High-speed spindles require perfectly balanced tool holders. Any vibration will create “chatter” marks on the surface. Chatter ruins both the finish and the dimensional accuracy. Use heat-shrink holders for the best possible runout control.

Advanced Metrology and Inspection Techniques

You cannot achieve what you cannot measure accurately. Therefore, inspection is the most important final step.

Using Coordinate Measuring Machines (CMM)

A high-precision CMM is essential for verifying tolerances. These machines should live in a temperature-controlled room. Furthermore, use scanning probes for a complete data picture. This ensures every cnc machining parts batch meets the client’s needs.

In-Process Probing

Smart factories use probes inside the CNC machine itself. This allows for mid-cycle adjustments before the final cut. It catches errors early and reduces scrap rates significantly. Probing is the best way to handle complex, expensive materials.

Optimized CAM Programming and Tool Paths

Software plays a huge role in achieving micron accuracy. Your CAM program must account for every variable.

Use small step-overs and consistent chip loads to reduce heat. Avoid sudden changes in tool direction during finishing passes. Smooth movements prevent the machine from “jerking” at high speeds. Furthermore, always use 5-axis machining to reduce part setups. Fewer setups mean fewer chances for alignment errors.

Material Selection and Stress Relieving

The raw material itself can cause precision issues. Internal stresses often cause parts to warp after machining.

Always source high-quality, certified metals for your projects. Perform stress-relieving heat treatments before the final finishing pass. This ensures the material stays “dead flat” during the last cut. Proper material prep is the foundation of CNC precision machining parts. It prevents frustrating surprises during the final inspection.

The Path to Micron Mastery

In summary, achieving +/- 0.001 mm is an elite achievement. It requires top-tier machines, stable environments, and expert programming. You must also prioritize high-end metrology to verify your success.

Every step of the process must be perfect. From tool selection to climate control, detail is everything. Mastering these factors will set your business apart in 2026. Chongxi delivers the highest quality CNC precision machining parts to win the market. The journey to precision starts with a commitment to excellence.