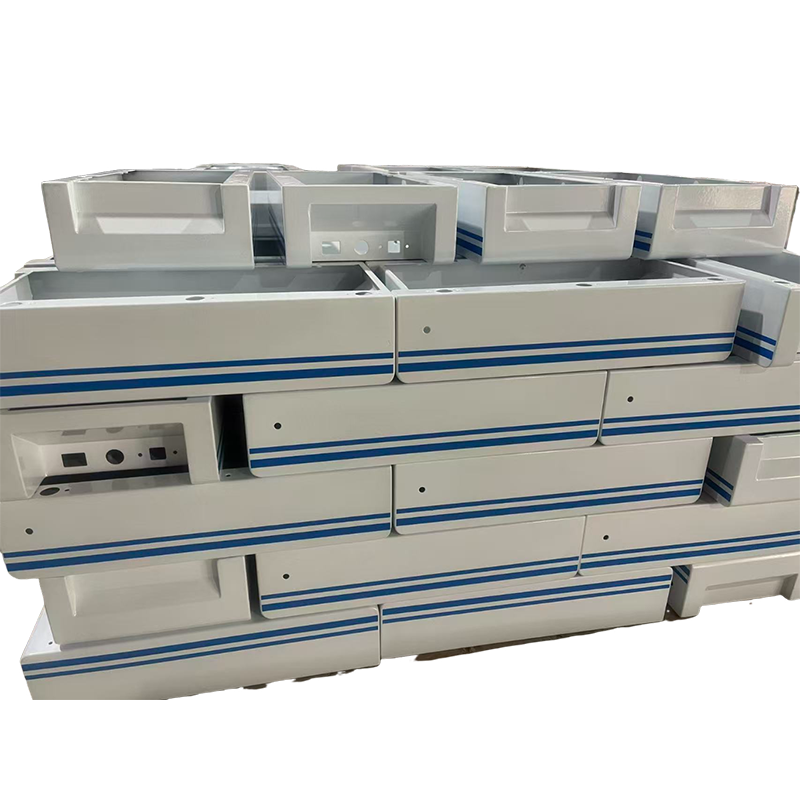

In the early days, we started with basic CNC milling machines. Every program had to be tested manually, every tool change relied on the technician’s experience, and scheduling was often done on paper.

Now, we’ve evolved into a fully digitized workshop with optimized production flow. Our progress includes:

-

Multi-axis CNC centers to enable complex and simultaneous operations;

-

A streamlined ERP and scheduling system for better order coordination;

-

Standardized processing parameters and drawing reviews for efficiency;

-

A full-process quality inspection and traceability system.

We don’t aim to be big—we aim to be precise, agile, and deeply focused. CNC machining is not just about cutting metal; it’s about refining a workflow that turns a drawing into consistent, high-quality output.