Meta Description: Explore how SPC tools and real-time monitoring ensure consistency and quality in high-volume CNC manufacturing.

Outline:

-

Introduction to SPC and Its Purpose

Define variation control, control charts, and process capability -

Core SPC Tools in Manufacturing

X-bar and R charts, histograms, Pareto analysis

Use of software and data collection systems -

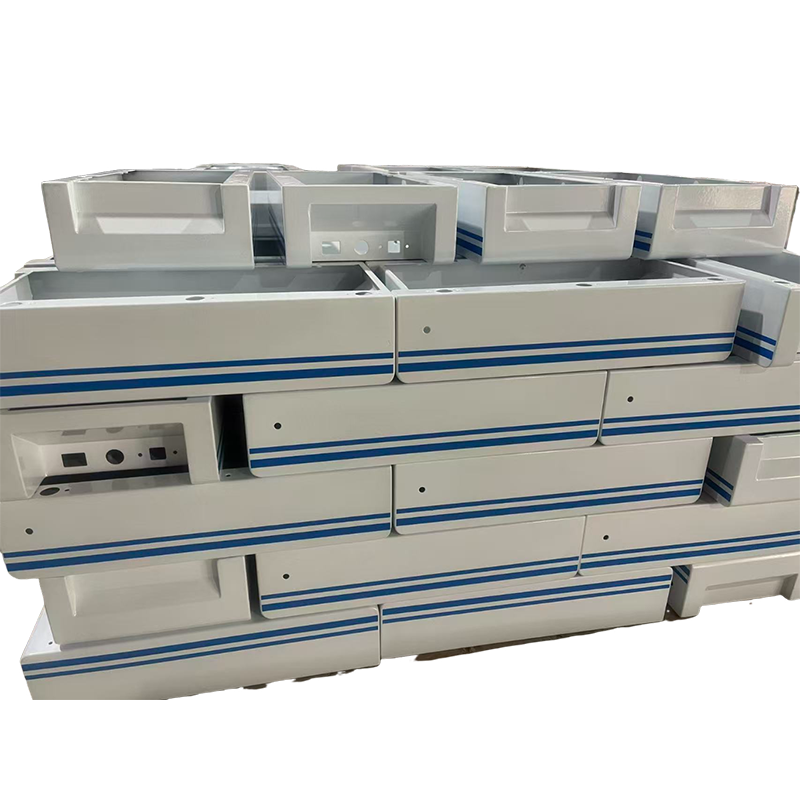

Application in CNC Workflow

Where SPC applies: raw material, machining, inspection

Monitoring key dimensions in real-time -

Benefits to Customer:

Fewer defects, traceability, predictable output

Demonstrable quality assurance for audits -

Chongxi’s SPC Integration

Real-time measurement integration

Corrective action tracking