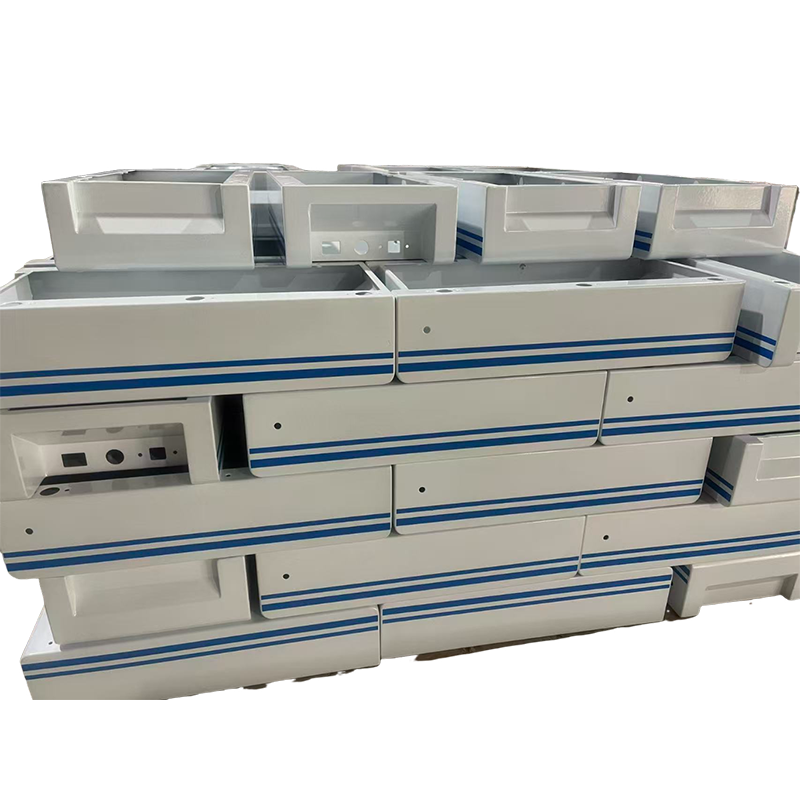

CNC machining is a manufacturing process that uses pre-programmed computer instructions to control the movement of cutting tools and machinery. Unlike manual machining, where the operator guides each movement, CNC machines execute programmed commands with extreme precision—every cut, every depth, and every spindle speed is controlled down to fractions of a millimeter.

The key advantages include:

-

High Accuracy – Consistent tolerances, often within ±0.005 mm for high-precision work.

-

Repeatability – Once a program is set, the same part can be produced hundreds or thousands of times with identical quality.

-

Complex Geometry – CNC machines can create intricate 3D shapes, deep cavities, fine details, and contours in one setup.

-

Efficiency – Reduced setup time and automation mean faster turnaround for both prototypes and mass production.